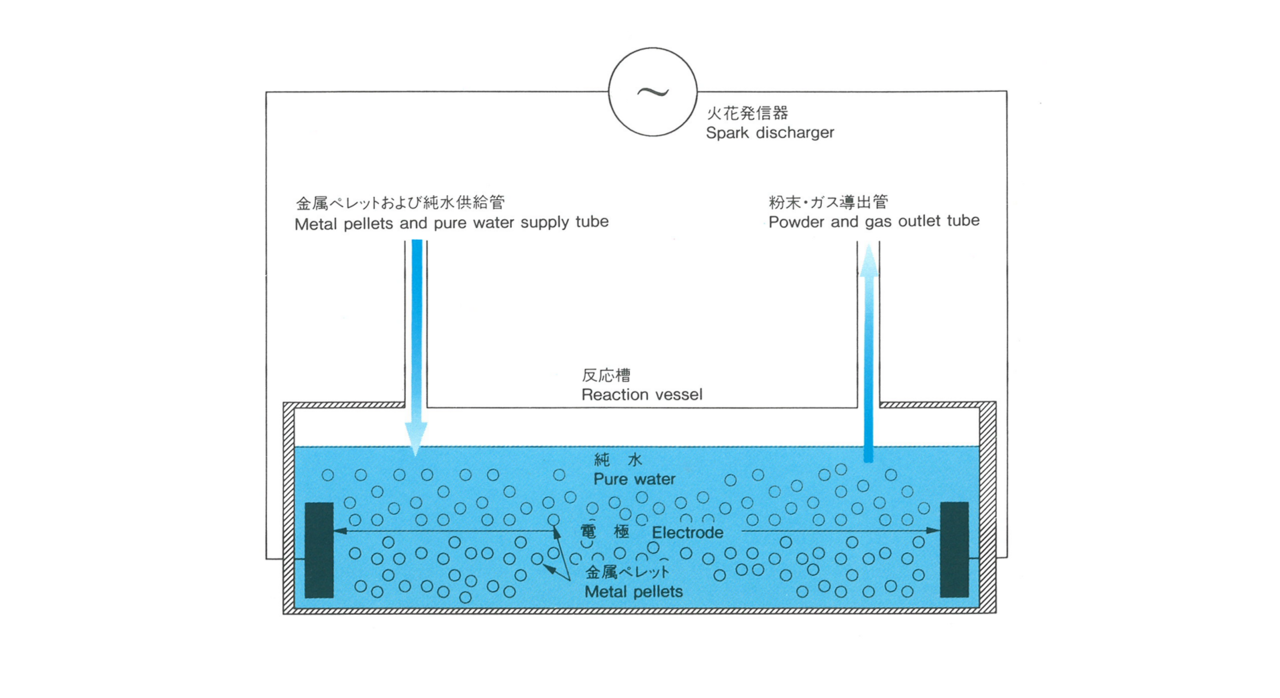

Iwatani-Process's Mechanism

The Iwatani-Process is method of manufacturing micron-order fine powders by the spark discharge technology. In this process, metal pellets are spark-discharged in pure water and a large amount of discharge points are formed on the metal pellets which are submerged in the water. At these discharge points occur a detachment phenomenon by fusion and evaporation, and a reaction with the decomposition products to produce a fine powder of Hydroxide and Oxide. Calcine these fine powders further and a variety of metal Oxide can be produced. With this method, there is never any contact with foreign impurities, unlike with other chemical and mechanical processes, making it possible to maintain high-purity. The spark-discharge method also allows us to manufacture composite powders with a very uniform composition.

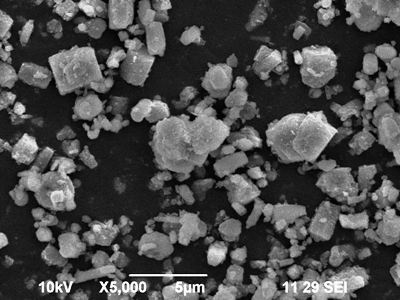

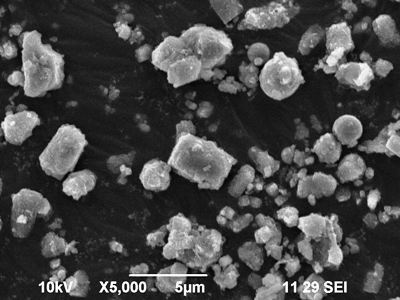

RA-30, RA-40

Center particle diameter10 micrometers up RA-30 and RA-40 are alfa-alumina made by

heating RH to high-temperatures.

| RA-30 | RA-40 | ||||

| Chemical composition | |||||

| Al (%) | 99.9 up | 99.99 up | |||

| Fe (ppm) | 150.0 | 7.0 | |||

| Si (ppm) | 150.0 | 18.0 | |||

| Cu (ppm) | 5.0 | 1.0 | |||

| Mg (ppm) | 3.0 | 1.0 | |||

| Ca (ppm) | 3.0 | 1.0 | |||

| Na (ppm) | 5.0 | 3.0 | |||

| Specific surface area (m2/g) | 3.5 | 3.5 | |||

| Cumulative particle size distribution | |||||

| 20 micrometers up (%) | 0.0 | 0.0 | |||

| 10 micrometers up (%) | 3.0 | 3.0 | |||

| 5 micrometers up (%) | 22.0 | 22.0 | |||

| 3 micrometers up (%) | 51.0 | 51.0 | |||

| 1 micrometers up (%) | 91.0 | 91.0 | |||

| 0.5 micrometers up (%) | 99.0 | 99.0 | |||

| 0.3 micrometers up (%) | 100.0 | 100.0 | |||

| Center particle diameter (μm) | 3.0 | 3.0 | |||

RG-30,RG-40

RG-30 and RG-40 are activated alumina made by heating RH to high-temperatures.

This consists of eta-alumina,theta-alumina

| RG-30 | RG-40 | ||||

| Chemical composition | |||||

| Al (%) | 99.9 up | 99.99 up | |||

| Fe (ppm) | 150.0 | 7.0 | |||

| Si (ppm) | 150.0 | 18.0 | |||

| Cu (ppm) | 5.0 | 1.0 | |||

| Mg (ppm) | 3.0 | 1.0 | |||

| Ca (ppm) | 3.0 | 1.0 | |||

| Na (ppm) | 5.0 | 3.0 | |||

| Specific surface area (m2/g) | 48.0 | 48.0 | |||

| Cumulative particle size distribution | |||||

| 20 micrometers up (%) | 0.0 | 0.0 | |||

| 10 micrometers up (%) | 1.0 | 1.0 | |||

| 5 micrometers up (%) | 10.0 | 10.0 | |||

| 3 micrometers up (%) | 35.0 | 35.0 | |||

| 1 micrometers up (%) | 91.0 | 91.0 | |||

| 0.5 micrometers up (%) | 99.0 | 99.0 | |||

| 0.3 micrometers up (%) | 100.0 | 100.0 | |||

| Center particle diameter (μm) | 2.2 | 2.2 | |||

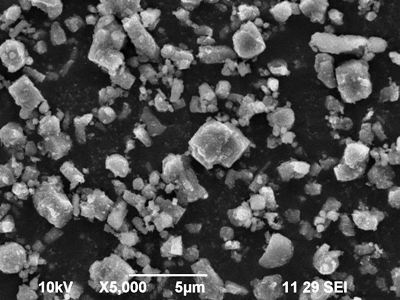

RK-30, RK-40

RK-30 and RK-40 are high activated alumina made by heating RH to high-temperatures.

RK is porous medium, so it has wide surface area and high adsorptivity.

| RK-30 | RK-40 | ||||

| Chemical composition | |||||

| Al (%) | 99.9 up | 99.99 up | |||

| Fe (ppm) | 150.0 | 4.0 | |||

| Si (ppm) | 150.0 | 18.0 | |||

| Cu (ppm) | 5.0 | 1.0 | |||

| Mg (ppm) | 3.0 | 1.0 | |||

| Ca (ppm) | 3.0 | 1.0 | |||

| Na (ppm) | 5.0 | 3.0 | |||

| Specific surface area (m2/g) | 150.0 | 150.0 | |||

| Cumulative particle size distribution | |||||

| 20 micrometers up (%) | 0.0 | 0.0 | |||

| 10 micrometers up (%) | 1.0 | 1.0 | |||

| 5 micrometers up (%) | 6.0 | 6.0 | |||

| 3 micrometers up (%) | 30.0 | 30.0 | |||

| 1 micrometers up (%) | 90.0 | 90.0 | |||

| 0.5 micrometers up (%) | 99.0 | 99.0 | |||

| 0.3 micrometers up (%) | 100.0 | 100.0 | |||

| Center particle diameter (μm) | 2.1 | 2.1 | |||

SA-1

SA-1, by processing the RA,is even more sinterable products with improved.

| SA-1 | |||

| Chemical composition | |||

| Al (%) | 99.9 up | ||

| Fe (ppm) | 8.0 | ||

| Si (ppm) | 18.0 | ||

| Cu (ppm) | 6.0 | ||

| Mg (ppm) | 6.0 | ||

| Ca (ppm) | 6.0 | ||

| Na (ppm) | 6.0 | ||

| Specific surface area (m2/g) | 4.5 | ||

| Cumulative particle size distribution | |||

| 20 micrometers up (%) | 0.0 | ||

| 10 micrometers up (%) | 0.0 | ||

| 5 micrometers up (%) | 1.0 | ||

| 3 micrometers up (%) | 4.0 | ||

| 1 micrometers up (%) | 30.0 | ||

| 0.5 micrometers up (%) | 75.0 | ||

| 0.3 micrometers up (%) | 97.0 | ||

| Center particle diameter (μm) | 0.6 | ||

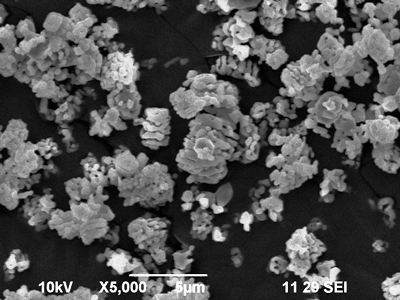

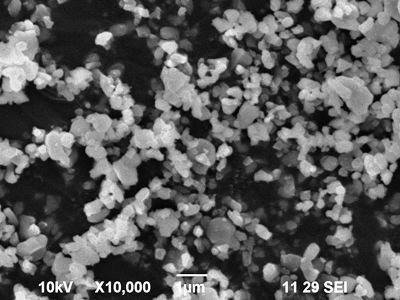

RH

RH is a fine powder of aluminum hydroxide of bayerite produced by the Iwatani-Process

from aluminum pellets.RH has the performance unique and different from the aluminun

hydroxide manufactured using the Bayer process.

| RH-30 | RH-40 | ||||

| Chemical composition | |||||

| Al (%) | 99.9 up | 99.99 up | |||

| Fe (ppm) | 100.0 | 5.0 | |||

| Si (ppm) | 100.0 | 13.0 | |||

| Cu (ppm) | 4.0 | 1.0 | |||

| Mg (ppm) | 2.0 | 1.0 | |||

| Ca (ppm) | 2.0 | 1.0 | |||

| Na (ppm) | 4.0 | 2.0 | |||

| Specific surface area (m2/g) | 200.0 | 200.0 | |||

| Cumulative particle size distribution | |||||

| 20 micrometers up (%) | 0.0 | 0.0 | |||

| 10 micrometers up (%) | 0.0 | 0.0 | |||

| 5 micrometers up (%) | 5.0 | 5.0 | |||

| 3 micrometers up (%) | 25.0 | 25.0 | |||

| 1 micrometers up (%) | 88.0 | 88.0 | |||

| 0.5 micrometers up (%) | 99.0 | 99.0 | |||

| 0.3 micrometers up (%) | 100.0 | 100.0 | |||

| Center particle diameter | 2.0 | 2.0 | |||

FGH

FGH is the product which was high-density more than FGL series and which has built the

alumina product made with Iwatani-Process into granularity.The particle diameter of FGH

has been completed by 1mm-about 3 mm.We can respond to the demand and adjust its

size.

| FGH | |||

| Chemical composition | |||

| Al (%) | 99.99 up | ||

| Fe (ppm) | 3.0 | ||

| Si (ppm) | 5.0 | ||

| Cu (ppm) | 1.0 | ||

| Mg (ppm) | 0.5 | ||

| Ca (ppm) | 2.0 | ||

| Na (ppm) | 0.5 | ||

| Ni (ppm) | 0.5 | ||

| Cr (ppm) | 0.3 | ||

| Ti (ppm) | 0.2 | ||

| Mn (ppm) | 0.1 | ||

| Apparent density (g/cm3) | 2.2 | ||

| Specific surface area (m2/g) | 0.1 | ||

FGL

FGL is the product which has built the alumina product made with Iwatani-Process

into granularity.The particle diameter of FGL has been completed by 1mm-about 3 mm.

We can respond to the demand and adjust its size.

| FGL | |||

| Chemical composition | |||

| Al (%) | 99.99 up | ||

| Fe (ppm) | 2.0 | ||

| Si (ppm) | 2.0 | ||

| Cu (ppm) | 1.0 | ||

| Mg (ppm) | 0.3 | ||

| Ca (ppm) | 0.3 | ||

| Na (ppm) | 0.1 | ||

| Ni (ppm) | 0.4 | ||

| Cr (ppm) | 0.3 | ||

| Ti (ppm) | 0.2 | ||

| Mn (ppm) | 0.1 | ||

| Apparent density (g/cm3) | 1.1 | ||

| Specific surface area (m2/g) | 3.0 | ||

MJ-30

MJ-30 is high density and superior sintering Magunesia made by heating MH to high-

temperture.

| MJ-30 | |||

| Chemical composition | |||

| Mg (%) | 99.9 up | ||

| Fe (ppm) | 10.0 | ||

| Si (ppm) | 30.0 | ||

| Cu (ppm) | 1.0 | ||

| Al (ppm) | 6.0 | ||

| Ca (ppm) | 1.0 | ||

| Na (ppm) | 1.0 | ||

| Specific surface area (m2/g) | 23.0 | ||

| Cumulative particle size distribution | |||

| 20 micrometers up (%) | 0.0 | ||

| 10 micrometers up (%) | 0.0 | ||

| 5 micrometers up (%) | 4.0 | ||

| 3 micrometers up (%) | 45.0 | ||

| 1 micrometers up (%) | 95.0 | ||

| 0.5 micrometers up (%) | 100.0 | ||

| 0.3 micrometers up (%) | 100.0 | ||

| Center particle diameter (μm) | 2.8 | ||

MTK

MTK-30 is made by immediately dehydrating Magunesia through heating MH to high-

temperture.

| MTK-30 | |||

| Chemical composition | |||

| Mg (%) | 99.9 up | ||

| Fe (ppm) | 10.0 | ||

| Si (ppm) | 30.0 | ||

| Cu (ppm) | 1.0 | ||

| Al (ppm) | 6.0 | ||

| Ca (ppm) | 1.0 | ||

| Na (ppm) | 1.0 | ||

| Specific surface area (m2/g) | 100.0 | ||

| Cumulative particle size distribution | |||

| 20 micrometers up (%) | 0.0 | ||

| 10 micrometers up (%) | 3.0 | ||

| 5 micrometers up (%) | 25.0 | ||

| 3 micrometers up (%) | 52.0 | ||

| 1 micrometers up (%) | 90.0 | ||

| 0.5 micrometers up (%) | 99.0 | ||

| 0.3 micrometers up (%) | 100.0 | ||

| Center particle diameter (μm) | 2.9 | ||

MH

MH-30 is high purity micronized Magunesium Hydroxide made by Iwatani-Process.

| MH-30 | |||

| Chemical composition | |||

| Mg (%) | 99.9 up | ||

| Fe (ppm) | 7.0 | ||

| Si (ppm) | 20.0 | ||

| Cu (ppm) | 1.0 | ||

| Al (ppm) | 6.0 | ||

| Ca (ppm) | 1.0 | ||

| Na (ppm) | 1.0 | ||

| Specific surface area (m2/g) | 23.0 | ||

| Cumulative particle size distribution | |||

| 20 micrometers up (%) | 0.0 | ||

| 10 micrometers up (%) | 0.0 | ||

| 5 micrometers up (%) | 4.0 | ||

| 3 micrometers up (%) | 50.0 | ||

| 1 micrometers up (%) | 95.0 | ||

| 0.5 micrometers up (%) | 100.0 | ||

| 0.3 micrometers up (%) | 100.0 | ||

| Center particle diameter (μm) | 2.9 | ||